Straight Run Belts

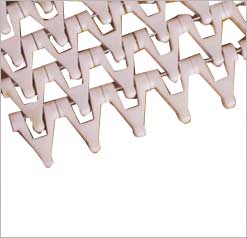

Plastic Modular Belts offer many advantages over conventional flat belt systems. These belts offer rugged yet flexible design features, which are increasingly used for food processing and conveying besides several engineering applications.

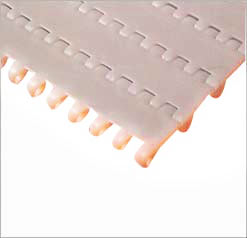

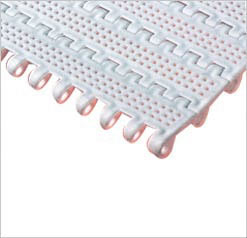

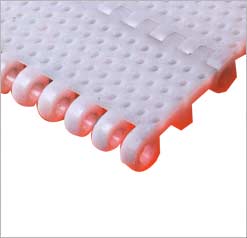

As the name suggests the belts are made up of plastic modules arranged in staggered (brick wall) pattern assembled on full-length polymer hinge rods, which gives an inherent strength to the belt. The modules are held in place on the rods by end-locks.

We offer Plastic Modular Straight Line Belts that is available in the model UMB-50 , UMB-38 , UMB-25 to our clients. These belts are extensively used as a general purpose light duty as well as heavy duty belt for several applications including straight line conveying, inclined conveying, washing line applications, warmers and cooling tunnels. Available with pitch of 25 / 38 / 50 mm, these are manufactured using different base polymers depending on the induced requirements. We offer these with transfer fingers width of 150 mm that make these suitable to use with RR (raised rib) model. Moreover, these are provided with guide strips that enables these for a smooth travel. Available in UHMWPE low-friction polymer, our complete range of belts is a combination of three different top surfaces and three different material to make it a multi-functional and can also be known as all-weather belt.

These Straight Line Belts are suitable for conveying applications of fruit and vegetable, processing meat, fish and seafood processing, bakery and snack food, packed juices and beverages, bucket elevators for rice, pulses and granular products as well as for various dip tank applications. Our product range includes: steel conveyor belt, cleated conveyor belt, plastic conveyor belt, pvc conveyor belt, stainless steel conveyor belt etc.

|

UMB-25 is a general purpose light duty conveyor belts which can be used for straight line conveying and also inclined conveying, washing, drying and drainage applications. Combination of 2 different top surfaces and 3 different materials is available to satisfy diverse end use applications. Accessories include vertical flights and side walls.

| Features |

| Pitch |

: |

25mm |

| Type |

: |

Hinge Driven |

| Material |

: |

PP (+1 to +105 deg C); Max. Tensile Load: 600 kg

HDPE (-40 to +80 deg C); Max. Tensile Load: 500 kg

Acetal (-25 to +95 deg C); Max. Tensile Load: 1000 kg |

| Pin Dia |

: |

5mm Nylon/Acetal |

| Widths available |

: |

150mm to 1500mm (Exact widths available on request) |

| Accessories |

: |

Vertical Flights in ht. = 5,10,15, 25, 50 & 75mm Side Walls ht. = 50 and 75mm |

| Drive Sprockets |

: |

12 Teeth (OD = 96mm and bore = 25mm round or 40x40mm SQ)

16 Teeth (OD = 130mm and bore = 25mm round or 40x40mm SQ)

20 Teeth (OD = 162mm and bore = 25mm round or 40x40mm SQ) |

|

|

|

UMB-50 HD is a versatile heavy duty and impact resistant belt with several application areas including food and vegetable processing, meat, fish and poultry applications, crates, cartons, jars conveying, packaging machines, Inspection tables and accumulators. It is available with a combination of 2 top surfaces and 3 different materials to ensure maximum end use possibilities.

| Features |

| Pitch |

: |

50 mm |

| Type |

: |

Hinge + Centre Driven |

| Material |

: |

PP (+1 to +105 deg C); Max. Tensile Load: 1200 kg

HDPE (-40 to +80 deg C); Max. Tensile Load: 1000 kg

Acetal (-25 to +95 deg C); Max. Tensile Load: 1800 kg |

| Pin Dia |

: |

8mm Nylon/Acetal |

| Widths available |

: |

150mm to 2500mm (Exact widths available on request) |

| Accessories |

: |

Vertical Flights in ht. = 25, 50, 75 & 100mm Side Walls ht. = 75 & 100mm |

| Drive Sprockets |

: |

8 Teeth (OD = 130mm and bore = 25mm round or 40x40mm SQ)

10 Teeth (OD = 162mm and bore = 40x40mm or 65x65mm SQ)

12 Teeth (OD = 192mm and bore = 40x40mm or 65x65mm SQ) |

|

|

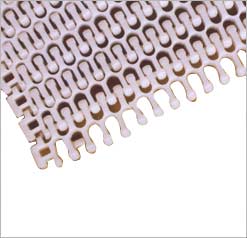

Side Flex Belts

We are offering a wide range of Side Flex Belts in varied models, such as USF-25 and USF-50. These belts can bend in all directions that results in enhancing the conveyor design possibilities. Our flex belts are offered with different pitch dimensions like 25 mm and 50 mm as per the application requirements. Moreover, these belts are manufactured using Acetal that has temperature ranging capacity of -25 �C to +95 �C and hence, these belts have maximum tensile load of 1600 kg. Available with the turning radius (innermost) of 2.8 times of the belt width, these belts are extensively used in various industries for conveying purposes. In addition, our range is available in UHMWPE that is a low-friction polymer along with guide strips that facilitates it for smooth travel.

Moreover, the straight line and curved conveyor sections, side flex belts can be combined into a single section resulting in smoother conveying and better cost efficiency. We provide Plastic Modular Belts, side flex belts, rubber conveyor belts, cleated conveyor belts at competitive prices.

|

Side flex modular belts USF 25 and USF 50 can bend in all directions resulting in enhanced conveyor design possibilities. Straight line and curved conveyor sections can be combined into a single section resulting in savings at many fronts.

| Features |

| MOC |

: |

Acetal (-25 to +95 deg C); Max Tensile Load: 400 kg

PP (+1 to +105 deg C); Max. Tensile Load: 250 kg |

| Pin Dia |

: |

5mm Nylon/Acetal |

| Approx. Turning Radius (Innermost) |

: |

2.2 times the belt width |

| Widths available |

: |

100mm to 600mm (Exact widths available on request) |

| Drive Sprockets |

: |

12 Teeth (0D = 97mm, Bore = 25mm round or 40x40mm SQ)

16 teeth (OD = 130mm, Bore = 25mm round or 40x40mm SQ)

20 teeth (OD = 160mm, Bore = 40x40mm or 65x65mm SQ) |

| Accessories |

: |

Vertical Flights in ht. = 5,10,15, 25, 50 & 75mm Side Walls ht. = 50 and 75mm |

| Drive Sprockets |

: |

12 Teeth (OD = 96mm and bore = 25mm round or 40x40mm SQ)

16 Teeth (OD = 130mm and bore = 25mm round or 40x40mm SQ)

20 Teeth (OD = 162mm and bore = 25mm round or 40x40mm SQ) |

|

|

|

Side flex modular belts USF 25 and USF 50 can bend in all directions resulting in enhanced conveyor design possibilities. Straight line and curved conveyor sections can be combined into a single section resulting in savings at many fronts.

| Features |

| MOC |

: |

Acetal (-25 to +95 deg C); Max.Tensile Load: 600 kg PP (+1 to +105 deg C); Max. Tensile Load: 300 kg |

| Pin Dia |

: |

6mm SS 304 |

| Approx. Turning Radius (Innermost) |

: |

2.6 times the belt width |

| Widths available |

: |

100mm to 900mm (exact widths available on request) |

| Drive Sprockets |

: |

8 Teeth (OD = 130mm and bore = 25mm round or 40x40mm SQ)

10 Teeth (OD = 161 mm and bore = 40x40mm or 65x65mm SQ)

12 Teeth (OD = 192mm and bore = 40x40mm or 65x65mm SQ) |

|

|